Precont PN4SM

At the moment, the product is not available in our warehouse.

After placing the order, we will notify you of the expected delivery date of the product.

Free delivery

from 1000 PLN (net)

Ask an experienced consultant:

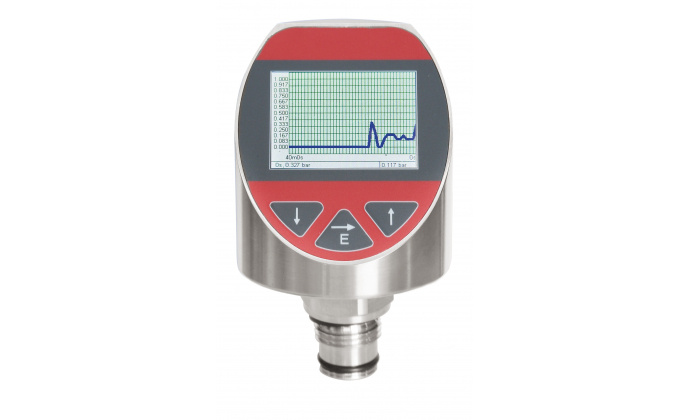

Pressure transmitter / Pressure switch with data memory for general applications up to 1000 bar Monitoring of absolute or relative pressure in gases, vapors, liquids and dust

Digital Pressure Sensor with metal diaphragm up to 1000 bar –

Latest generation with a large display, analog and 4 pnp switching outputs

- Measuring range up to 1000bar

- Full text programming with colour display

- Datalogger for 500’000 measuring points

The device Precont PN4SM is an electronic pressure transmitter / pressure switch for monitoring, control as well as continuous measurement of pressures in gases, vapors, liquids and dusts.

Due to the device construction with measuring ranges from -1 bar to 1000 bar (gauge), measuring ranges from 0 bar to 1000 bar (absolute), measuring spans from 400 mbar to 1000 bar, process temperatures from –40°C to +125°C, process material CrNi-steel as well as the availability of industrial standard process connections like thread ISO 228-1 (EN 837 manometer, front-flush) the device is especially suitable for the use for machinery and plant engineering, air-conditioning and refrigeration plant engineering, hydraulic and pneumatic systems, process industry, environmental technology, facility and building automation.

The device Precont PN4SM is suitable for demanding measuring requirements.

Due to its high accuracy and the high flexibility of configuration, the device can be suited a wide variety of applications.

The front-flush diaphragm has been specifically designed for the measurement of viscous, paste-like, adhesive, crystallizing, particle-laden and contaminated media, which would clog the pressure channel of conventional process connections.

The robust design and the high-quality workmanship turns the device into a very high quality product, which even the most adverse environmental conditions cannot affect, whether low temperatures when used outdoors, high shock and vibration or aggressive media.

A captive laser marking of the type label ensures the identifiability throughout the entire lifetime of the device.

Obviously is the optional marking of a measurement point designation resp. TAG, a customer label or of a neutral type label, of course also per laser marking.

A LABS-free resp. silicone-free version, a factory calibration with calibration certificate and a customer specific configuration resp. preset is also optionally available like factory certifications for drink water resp. food suitability.

| Versorgungsspannung | |

| Ausgangssignal 0(4)…20mA | 9 V…30 V DC |

| Ausgangssignal 0…10V | 14 V…30 V DC |

| Analogausgang | |

| Arbeitsbereich | 0…20mA: 0…20,5mA, max. 22mA 4…20mA: 3,8…20,5mA, min. 3,6mA, max. 22mA 0…10V: 0…10,5V, max. 11V |

| Zulässige Bürde | 0(4)…20mA: ≤ (US-9V) / 22mA 0…10V: ≥ UOut / 3mA |

| Sprungantwortzeit | ≤ 15ms (td = 0s) |

| Bereitschaftszeit | ≤ 1s |

| Schaltausgang PNP S1 / S2 / S3 / S4 | |

| Funktion | PNP-schaltend auf +L |

| Ausgangsstrom | IL 0…≤ 200mA Strombegrenzt Kurzschlussfest |

| Sprungantwortzeit | ≤ 25ms (td = 0s) |

| Schaltzyklen | ≥ 100.000.000 |

| Bluetooth® Interface | |

| Version | Bluetooth® 2.1 + EDR |

| Spezifikation | Klasse 2 |

| Sendeleistung | ≤ 2,5mW / 4dBm |

| Reichweite | ≤ 10m |

| Messgenauigkeit | |

| Kennlinienabweichung | ≤ ±0,15% FS ≤ ±0,5% FS |

| Langzeitdrift | ≤ ±0,2% FS/Jahr |

| Temperaturabweichung | Messbereich ≤ 25bar: ≤ ±0,02% FS/K (0°C…+80°C) Messbereich ≤ 25bar: ≤ ±0,03% FS/K (-40°C…0°C / +80°C…+125°C) Messbereich ≥ 40bar: ≤ ±0,02% FS/K (-40°C…+100°C) Messbereich ≥ 40bar: ≤ ±0,03% FS/K (+100°C…+125°C) |

| Werkstoffe | |

| Membrane (prozessberührend) | Messbereich ≤ 1bar: Keramik Al2O3 – 99,7% (SIP-geeignet) Messbereich ≥ 1,6bar: Keramik Al2O3 – 96% (SIP-geeignet) Prozessanschluss 1/2/4/6/7/A/N/M/P/L/S/T: Keramik Al2O3 – 99,9% (CIP-SIP-geeignet) |

| Prozessanschluss (prozessberührend) | Stahl 1.4404 (316L) Stahl 1.4571 (316Ti) |

| Anschlussgehäuse | CrNi-Stahl |

| Bedienoberfläche | PES |

| Dichtungen (prozessberührend) | FPM-Fluorelastomer (z.B. Vition®) EPDM – Ethylen-Propylen-Dienmonomer, FDA-gelistet FKKM – Perfluorelastomer (z.B. Kalrez®) FKKM hd – Perfluorelastomer hochdicht |

| Umgebungsbedingungen | |

| Umgebungstemperatur | -20°C…+70°C |

| Prozesstemperaturen | -40°C…+125°C |

| Prozessdruckbereiche | 0,4bar … 1000bar typabhängig |

| Schutzart | IP68 (EN/IEC 60529) |

(

(